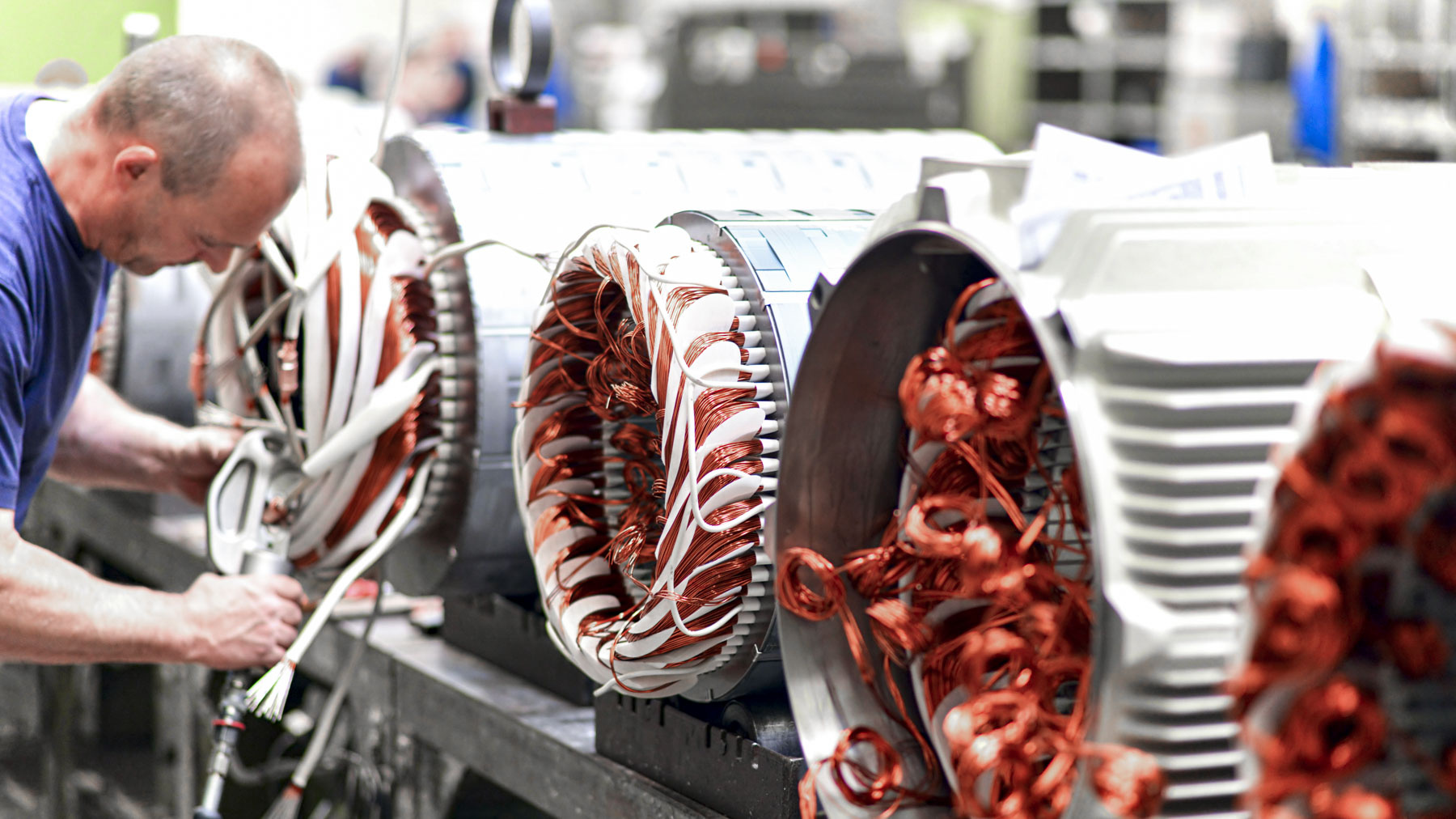

Electric Motors

Our motors for thruster, pump and winch drives are designed for use under extremely harsh conditions in the marine and offshore environment.

The motors are built in Europe and are delivered according to current ship classification standards.

The motors used by REMAT are designed in such a way that optimal efficiency is achieved in combination with the frequency controller. Mass inertia, power factor, efficiency, input voltage and insulation of the windings are optimized.

The motors are built in Europe and are delivered according to current ship classification standards.

The motors used by REMAT are designed in such a way that optimal efficiency is achieved in combination with the frequency controller. Mass inertia, power factor, efficiency, input voltage and insulation of the windings are optimized.

ASYNCHRONOUS ENGINES

Low-voltage asynchronous motors are supplied with a voltage of up to 690 V. Depending on the installation location and application, we supply the motors with a protection class of IP 23 to IP 56, (holding) brakes, mounted air/water coolers, customer-specific terminal boxes, special mounting dimensions. , etc.

PERMANENT MAGNET MOTORS

REMAT recognized the energy-saving potential of the future-oriented permanent magnet technology at an early stage. Electric motors equipped with permanent magnet technology achieve efficiency of up to 98% and more. This makes them one of the most efficient drives in the energy efficiency class IE4. The reduced inertia of the PM rotor (especially in the low speed range) results in lower starting energy and a further increase in energy efficiency. An important advantage, especially for dynamic drives with constantly changing speed, such as DP systems. These motors achieve very high efficiency in both the full and partial load range. Using the latest frequency converter technology, we can replace the entire range of commercial electric motors with PM technology.

Low-voltage asynchronous motors are supplied with a voltage of up to 690 V. Depending on the installation location and application, we supply the motors with a protection class of IP 23 to IP 56, (holding) brakes, mounted air/water coolers, customer-specific terminal boxes, special mounting dimensions. , etc.

PERMANENT MAGNET MOTORS

REMAT recognized the energy-saving potential of the future-oriented permanent magnet technology at an early stage. Electric motors equipped with permanent magnet technology achieve efficiency of up to 98% and more. This makes them one of the most efficient drives in the energy efficiency class IE4. The reduced inertia of the PM rotor (especially in the low speed range) results in lower starting energy and a further increase in energy efficiency. An important advantage, especially for dynamic drives with constantly changing speed, such as DP systems. These motors achieve very high efficiency in both the full and partial load range. Using the latest frequency converter technology, we can replace the entire range of commercial electric motors with PM technology.

Motors designed to combine with frequency-controlled drive systems in demanding maritime applications.